- Butt welding fittings

- bends

- T- X- Y- pieces

- T- and Y-bends

- reducers

- caps and heads

- collars

- branch saddles

- orbital fittings

- ANSI / ASME

- Industrial valves

- ball valves

- actuators

- drain cocks

- gate valves

- globe valves

- non-return valves

- Y-strainers

- control technology

- Flanges

- welding neck flanges

- threaded flanges

- blind flanges

- plate flanges

- loose plate flanges

- collars

- flange-fittings

- ANSI/ ASME

- other

- Systems

- TEEKAY

- Victaulic

- press fittings

- quick couplings

- clamp connections

- cutting rings

- DIN 11864/ DIN 11853

- railing construction

- Beverage fittings

- unions

- fittings

- pipe clamps

- Tri-Clamp

- valves & cocks

- flange connections

- inspection glasses

- filter & strainers

- spray balls

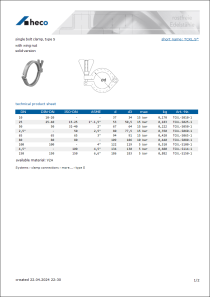

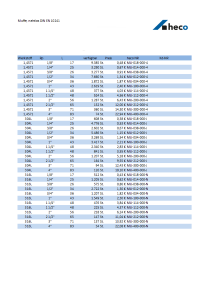

single bolt clamp, type STCKL.S

single bolt clamp, type S with wing nut solid version

Tri-clamp connections DIN 32676

Fields of application

Tri-clamp connections are used wherever quick assembly and disassembly is required,

the spaces are tight, or conventional flange connections with screws and nuts are too heavy

or too expensive. Typical areas of application include exhaust lines in engine construction;

containers, filters, pumps, and valves in the food, pharmaceuticals, and chemical plant engineering.

Mounting

During assembly, the clamp seal is placed on one of the two clamp sleeves so that the outer

edge of the seal wraps around the flange of the clamp sleeve. Then you place the other clamp

sleeve on the seal. The clamp sleeve and the seal are therefore coaxially centered. After that,

the clamp is placed around the flange of the clamp sleeve and closed (optionally available with

safety lock). The seal deforms in this case so that a smoother passage free of dead space and

a sealed connection are created.

The pressure level listed corresponds to the maximum operating pressure at 150°C.

extended product description

Stainless steel Tri-Clamp moretype S

single bolt clamp, type STCKL.S

Tri-clamp connections DIN 32676

Fields of application

Tri-clamp connections are used wherever quick assembly and disassembly is required,

the spaces are tight, or conventional flange connections with screws and nuts are too heavy

or too expensive. Typical areas of application include exhaust lines in engine construction;

containers, filters, pumps, and valves in the food, pharmaceuticals, and chemical plant engineering.

Mounting

During assembly, the clamp seal is placed on one of the two clamp sleeves so that the outer

edge of the seal wraps around the flange of the clamp sleeve. Then you place the other clamp

sleeve on the seal. The clamp sleeve and the seal are therefore coaxially centered. After that,

the clamp is placed around the flange of the clamp sleeve and closed (optionally available with

safety lock). The seal deforms in this case so that a smoother passage free of dead space and

a sealed connection are created.

The pressure level listed corresponds to the maximum operating pressure at 150°C.

This view is not optimized for mobile devices.

You can change back to desktop view.

This view is not optimized for mobile devices.

You can change back to desktop view.