- Butt welding fittings

- bends

- T- X- Y- pieces

- T- and Y-bends

- reducers

- caps and heads

- collars

- branch saddles

- orbital fittings

- ANSI / ASME

- Industrial valves

- ball valves

- actuators

- drain cocks

- gate valves

- globe valves

- non-return valves

- Y-strainers

- control technology

- Flanges

- welding neck flanges

- threaded flanges

- blind flanges

- plate flanges

- loose plate flanges

- collars

- flange-fittings

- ANSI/ ASME

- other

- Systems

- TEEKAY

- Victaulic

- press fittings

- quick couplings

- clamp connections

- cutting rings

- DIN 11864/ DIN 11853

- railing construction

- Beverage fittings

- unions

- fittings

- pipe clamps

- Tri-Clamp

- valves & cocks

- flange connections

- inspection glasses

- filter & strainers

- spray balls

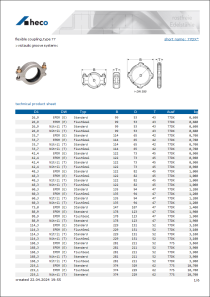

flexible coupling, type 7777DX

flexible coupling, type 77 >victaulic groove system<

Flexible coupling made of stainless steel

Victaulic No. 77S

Flexible grooved standard couplings allow controlled linear as well as angular and rotary

motion at all connection points to compensate for expansions/contractions, settling, vibrations,

noises, as well as other motions of the pipe system.

Material specifications

Housing:

Stainless steel for corrosion resistance and strength.

Standard version

| Size | Material |

|---|---|

| 20 mm/ 3/4" | CF8M/Typ 316 |

| 25 - 100 mm/ 1" - 4" | CE8MN/ Duplex |

| 150 - 450 mm/ 6" - 18" | CF8M/Typ 316 |

Seal:

Standard:

• Grade “EW” EPDM

EPDM (Green W color code). Temperature –30°F to +230°F/–34°C to +110°C. Recommended for

hot water service within the specified temperature range plus a variety of dilute acids, oil-free air

and many chemical services. WRAS-certified material with approved microbiological resistance to

BS 6920 for cold and hot potable water service up to +149°F/+65°C. NOT RECOMMENDED FOR

PETROLEUM SERVICES.

Optional Gaskets: (specify choice)

• Grade “E” EPDM

EPDM (Green Stripe color code). Temperature range –30°F to +230°F/–34°C to +110°C.

Recommended for cold and hot water service within the specified temperature range plus a

variety of dilute acids, oil-free air and many chemical services. UL Classified to ANSI/NSF 61 for

cold +86°F/+30°C and hot +180°F/+82°C potable water service. NOT RECOMMENDED FOR

PETROLEUM SERVICES.

• Grade “T” nitrile

Nitrile (Orange Stripe color code). Temperature range –20°F to +180°F/–29°C to +82°C.

Recommended for petroleum products, air with oil vapors, vegetable and mineral oils within the

specified temperature range. Not recommended for hot water services over

+150°F/+66°C or for hot dry air over +140°F/+60°C.

• Grade “O” fluoroelastomer

Fluoroelastomer (Blue Stripe color code). Temperature range +20°F to + 300°F/–7°C to +149°C.

Recommended for many oxidizing acids, petroleum oils, halogenated hydrocarbons, lubricants,

hydraulic fluids, organic liquids and air with hydrocarbons.

Performance data of the flexible coupling system

Nominal pressures

Pressure depending on nominal size and wall thickness

Design

| D x s | Sched. | bar |

|---|---|---|

| 26,9 x 1,65 | 5S | 22,41 |

| 26,9 x 2,11 | 10S | 34,45 |

| 26,9 x 2,87 | 40S | 51,75 |

| 26,9 x 2,87 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 33,7 x 1,65 | 5S | 22,41 |

| 33,7 x 2,77 | 10S | 34,45 |

| 33,7 x 3,38 | 40S | 51,75 |

| 33,7 x 3,38 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 42,4 x 1,65 | 5S | 22,41 |

| 42,4 x 2,77 | 10S | 34,45 |

| 42,4 x 3,56 | 40S | 51,75 |

| 42,4 x 3,56 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 48,3 x 1,65 | 5S | 22,41 |

| 48,3 x 2,77 | 10S | 34,45 |

| 48,3 x 3,68 | 40S | 51,75 |

| 48,3 x 3,68 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 60,3 x 1,65 | 5S | 22,41 |

| 60,3 x 2,77 | 10S | 34,45 |

| 60,3 x 3,91 | 40S | 51,75 |

| 60,3 x 3,91 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 88,9 x 2,11 | 5S | 17,24 |

| 88,9 x 3,05 | 10S | 27,60 |

| 88,9 x 5,49 | 40S | 51,75 |

| 88,9 x 5,49 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 114,3 x 2,11 | 5S | 15,51 |

| 114,3 x 3,05 | 10S | 24,13 |

| 114,3 x 6,02 | 40S | 27,60 |

| 114,3 x 6,02 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 168,3 x 2,77 | 5S | 8,62 |

| 168,3 x 3,40 | 10S | 13,79 |

| 168,3 x 7,11 | 40S | 20,68 |

| 168,3 x 7,11 | 40S* | 82,73 |

40S* = milled groove duplex tube

Performance data of the flexible coupling system

| D x s | Sched. | bar |

|---|---|---|

| 219,1 x 2,77 | 5S | 5,17 |

| 219,1 x 3,76 | 10S | 8,62 |

| 219,1 x 8,18 | 40S | 20,68 |

| -------------- | ------ | ------- |

| 273,0 x 3,40 | 5S | 4,19 |

| 273,0 x 4,19 | 10S | 5,17 |

| 273,0 x 9,27 | 40S | 20,68 |

| -------------- | ------ | ------- |

| 323,9 x 3,96 | 5S | 4,57 |

| 323,9 x 4,57 | 10S | 8,62 |

| 323,9 x 9,53 | 40S | 20,68 |

Permissible pipe end gap

| Pipe OØ | max. |

|---|---|

| 26,9 - 101,6 | 1,6 |

| 108,0 - 610,0 | 3,2 |

All specifications in mm

extended product description

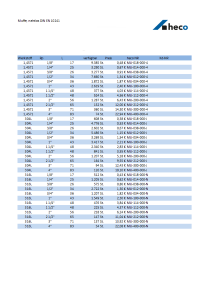

Stainless steel Victaulic Standard Nutsystem flex & type 77DX/77S

flexible coupling, type 7777DX

Flexible coupling made of stainless steel

Victaulic No. 77S

Flexible grooved standard couplings allow controlled linear as well as angular and rotary

motion at all connection points to compensate for expansions/contractions, settling, vibrations,

noises, as well as other motions of the pipe system.

Material specifications

Housing:

Stainless steel for corrosion resistance and strength.

Standard version

| Size | Material |

|---|---|

| 20 mm/ 3/4" | CF8M/Typ 316 |

| 25 - 100 mm/ 1" - 4" | CE8MN/ Duplex |

| 150 - 450 mm/ 6" - 18" | CF8M/Typ 316 |

Seal:

Standard:

• Grade “EW” EPDM

EPDM (Green W color code). Temperature –30°F to +230°F/–34°C to +110°C. Recommended for

hot water service within the specified temperature range plus a variety of dilute acids, oil-free air

and many chemical services. WRAS-certified material with approved microbiological resistance to

BS 6920 for cold and hot potable water service up to +149°F/+65°C. NOT RECOMMENDED FOR

PETROLEUM SERVICES.

Optional Gaskets: (specify choice)

• Grade “E” EPDM

EPDM (Green Stripe color code). Temperature range –30°F to +230°F/–34°C to +110°C.

Recommended for cold and hot water service within the specified temperature range plus a

variety of dilute acids, oil-free air and many chemical services. UL Classified to ANSI/NSF 61 for

cold +86°F/+30°C and hot +180°F/+82°C potable water service. NOT RECOMMENDED FOR

PETROLEUM SERVICES.

• Grade “T” nitrile

Nitrile (Orange Stripe color code). Temperature range –20°F to +180°F/–29°C to +82°C.

Recommended for petroleum products, air with oil vapors, vegetable and mineral oils within the

specified temperature range. Not recommended for hot water services over

+150°F/+66°C or for hot dry air over +140°F/+60°C.

• Grade “O” fluoroelastomer

Fluoroelastomer (Blue Stripe color code). Temperature range +20°F to + 300°F/–7°C to +149°C.

Recommended for many oxidizing acids, petroleum oils, halogenated hydrocarbons, lubricants,

hydraulic fluids, organic liquids and air with hydrocarbons.

Performance data of the flexible coupling system

Nominal pressures

Pressure depending on nominal size and wall thickness

Design

| D x s | Sched. | bar |

|---|---|---|

| 26,9 x 1,65 | 5S | 22,41 |

| 26,9 x 2,11 | 10S | 34,45 |

| 26,9 x 2,87 | 40S | 51,75 |

| 26,9 x 2,87 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 33,7 x 1,65 | 5S | 22,41 |

| 33,7 x 2,77 | 10S | 34,45 |

| 33,7 x 3,38 | 40S | 51,75 |

| 33,7 x 3,38 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 42,4 x 1,65 | 5S | 22,41 |

| 42,4 x 2,77 | 10S | 34,45 |

| 42,4 x 3,56 | 40S | 51,75 |

| 42,4 x 3,56 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 48,3 x 1,65 | 5S | 22,41 |

| 48,3 x 2,77 | 10S | 34,45 |

| 48,3 x 3,68 | 40S | 51,75 |

| 48,3 x 3,68 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 60,3 x 1,65 | 5S | 22,41 |

| 60,3 x 2,77 | 10S | 34,45 |

| 60,3 x 3,91 | 40S | 51,75 |

| 60,3 x 3,91 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 88,9 x 2,11 | 5S | 17,24 |

| 88,9 x 3,05 | 10S | 27,60 |

| 88,9 x 5,49 | 40S | 51,75 |

| 88,9 x 5,49 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 114,3 x 2,11 | 5S | 15,51 |

| 114,3 x 3,05 | 10S | 24,13 |

| 114,3 x 6,02 | 40S | 27,60 |

| 114,3 x 6,02 | 40S* | 82,73 |

| ------------- | ------ | ------ |

| 168,3 x 2,77 | 5S | 8,62 |

| 168,3 x 3,40 | 10S | 13,79 |

| 168,3 x 7,11 | 40S | 20,68 |

| 168,3 x 7,11 | 40S* | 82,73 |

40S* = milled groove duplex tube

Performance data of the flexible coupling system

| D x s | Sched. | bar |

|---|---|---|

| 219,1 x 2,77 | 5S | 5,17 |

| 219,1 x 3,76 | 10S | 8,62 |

| 219,1 x 8,18 | 40S | 20,68 |

| -------------- | ------ | ------- |

| 273,0 x 3,40 | 5S | 4,19 |

| 273,0 x 4,19 | 10S | 5,17 |

| 273,0 x 9,27 | 40S | 20,68 |

| -------------- | ------ | ------- |

| 323,9 x 3,96 | 5S | 4,57 |

| 323,9 x 4,57 | 10S | 8,62 |

| 323,9 x 9,53 | 40S | 20,68 |

Permissible pipe end gap

| Pipe OØ | max. |

|---|---|

| 26,9 - 101,6 | 1,6 |

| 108,0 - 610,0 | 3,2 |

All specifications in mm

This view is not optimized for mobile devices.

You can change back to desktop view.

This view is not optimized for mobile devices.

You can change back to desktop view.