- Butt welding fittings

- bends

- T- X- Y- pieces

- T- and Y-bends

- reducers

- caps and heads

- collars

- branch saddles

- orbital fittings

- ANSI / ASME

- Industrial valves

- ball valves

- actuators

- drain cocks

- gate valves

- globe valves

- non-return valves

- Y-strainers

- control technology

- Flanges

- welding neck flanges

- threaded flanges

- blind flanges

- plate flanges

- loose plate flanges

- collars

- flange-fittings

- ANSI/ ASME

- other

- Systems

- TEEKAY

- Victaulic

- press fittings

- quick couplings

- clamp connections

- cutting rings

- DIN 11864/ DIN 11853

- railing construction

- Beverage fittings

- unions

- fittings

- pipe clamps

- Tri-Clamp

- valves & cocks

- flange connections

- inspection glasses

- filter & strainers

- spray balls

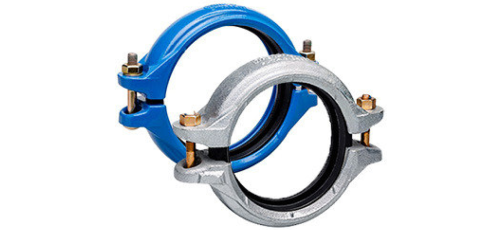

rigid coupling, type E497E497

rigid coupling, type E497 installation-ready for thin wall ss tube >victaulic groove system<

>>StrengThin™ 100 system<<

Rigid coupling, installation-ready for thin wall stainless steel pipe

Victaulic® StrengThin™ 100 System - Style E497

| Function |

|---|

| • The rigid coupling does not accommodate expansion, contraction, rotation or angular deflection |

| • Patented Victaulic Installation-Ready™ technology |

| • No torque requirements |

| Design |

|---|

| • Designed for use on stainless steel pipe per EN 10217-7 |

| • Exclusively for use on 1.4301/1.4307 (304/304L) or 1.4401/1.4404 (316/316L) |

| • Maximum Working Pressure: 16 bar (accommodates pressures ranging from full vacuum) |

| • Exclusively for use with Victaulic StrengThin™ 100 groove profile |

Pipe wall thickness and maximum permissible end load for 16 bar

| Size | [s] max. | [s] min. | [N] max. |

|---|---|---|---|

| DN 50/ 60,3 | 2,7 mm | 1,6 mm | 4573 |

| DN 65/ 76,1 | 2,7 mm | 1,6 mm | 7295 |

| DN 80/ 88,9 | 2,7 mm | 1,6 mm | 9928 |

| DN 100/ 114,3 | 2,7 mm | 1,6 mm | 16414 |

| DN 125/ 139,7 | 3,0 mm | 2,0 mm | 24519 |

| DN 150/ 168,3 | 3,0 mm | 2,0 mm | 35572 |

| DN 200/ 219,1 | 3,7 mm | 3,0 mm | 56937 |

| DN 250/ 273,0 | 4,2 mm | 3,0 mm | 85596 |

| DN 300/ 323,9 | 4,5 mm | 3,0 mm | 126928 |

| Material |

|---|

| • Housing: Ductile iron conforming to ASTM A536, Klasse 65-45-12; EN 1563; ISO 1083 |

| • Track bolts: made of carbon steel with oval neck (metric) zinc electroplated |

| • Heavy hex nuts: made of carbon steel per ASTM A563M Klasse 9 (metric) |

| • Pipe preparation: Victaulic StrengThin™ 100 groove profile |

| Housing coating |

|---|

| • Standard: Hot dipped galvanized |

| • Optional: Orange enamel |

| • Optional: Blue zinc coating; Atmospheric corrosivity category C4 in accordance with ISO 12944 |

Rigid coupling, installation-ready for thin wall stainless steel pipe

Victaulic® StrengThin™ 100 System - Style E497

GASKET-SPECIFICATION

| Grade „EHP” EPDM |

|---|

| • EHP (Red and Green stripe color code)) |

| • Temperature range -34 ºC to +120 ºC/-30 ºF to +250 ºF. |

| • May be specified for hot water service within the specified temperature range plus |

| a variety of dilute acids, oil-free air and many chemical services. |

| • UL Classified in accordance with ANSI/NSF 61 for cold +73ºF/+23ºC and |

| hot +180ºF/+82ºC potable water service and ANSI/NSF 372. |

| • NOT COMPATIBLE FOR PETROLEUM SERVICES OR STEAM SERVICES. |

| Grade „EF” EPDM |

|---|

| • EPDM (Green “X” color code) |

| • Temperature range -34 °C to +110 °C/-30 °F to +230 °F. |

| • May be specified for hot and cold water service within the specified temperature range plus |

| a variety of dilute acids, oil-free air and many chemical services. |

| • WRAS approved material to BS 6920 for cold and hot potable water service |

| up to +65 °C/+149 °F. |

| • DVGW approved material per DVGW W 270, KTW 1.3.13, |

| and EN 681-1 Type WA cold potable and Type WB hot potable water service |

| • NOT COMPATIBLE FOR USE WITH PETROLEUM SERVICES OR STEAM SERVICES. |

| • Grade „T” Nitrile |

|---|

| • Nitrile (Orange stripe color code) |

| • Temperature range -29 °C to +82 °C/-20 °F to +180 °F. |

| • May be specified for petroleum products, hydrocarbons, air with oil vapors, and vegetable |

| and mineral oils within the specified temperature range. |

| • Not compliant for hot dry air over +60 °C/+140 °F and water over +66 °C/+150 °F. |

| • COMPATIBLE FOR USE WITH HOT WATER SERVICES OR STEAM SERVICES. |

Exclusively for use with fittings, valves, accessories and pipe which feature ends

formed with the Victaulic StrengThin™ 100 groove profile.

>victaulic groove system<

>>StrengThin™ 100 system<<

extended product description

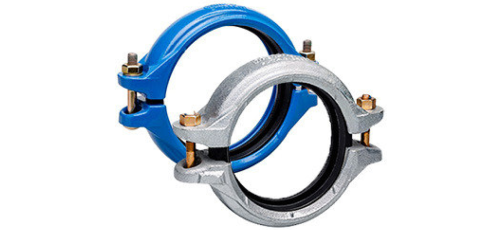

Stainless steel Victaulic StrengThin™ 100 rigid coupling

rigid coupling, type E497E497

Rigid coupling, installation-ready for thin wall stainless steel pipe

Victaulic® StrengThin™ 100 System - Style E497

| Function |

|---|

| • The rigid coupling does not accommodate expansion, contraction, rotation or angular deflection |

| • Patented Victaulic Installation-Ready™ technology |

| • No torque requirements |

| Design |

|---|

| • Designed for use on stainless steel pipe per EN 10217-7 |

| • Exclusively for use on 1.4301/1.4307 (304/304L) or 1.4401/1.4404 (316/316L) |

| • Maximum Working Pressure: 16 bar (accommodates pressures ranging from full vacuum) |

| • Exclusively for use with Victaulic StrengThin™ 100 groove profile |

Pipe wall thickness and maximum permissible end load for 16 bar

| Size | [s] max. | [s] min. | [N] max. |

|---|---|---|---|

| DN 50/ 60,3 | 2,7 mm | 1,6 mm | 4573 |

| DN 65/ 76,1 | 2,7 mm | 1,6 mm | 7295 |

| DN 80/ 88,9 | 2,7 mm | 1,6 mm | 9928 |

| DN 100/ 114,3 | 2,7 mm | 1,6 mm | 16414 |

| DN 125/ 139,7 | 3,0 mm | 2,0 mm | 24519 |

| DN 150/ 168,3 | 3,0 mm | 2,0 mm | 35572 |

| DN 200/ 219,1 | 3,7 mm | 3,0 mm | 56937 |

| DN 250/ 273,0 | 4,2 mm | 3,0 mm | 85596 |

| DN 300/ 323,9 | 4,5 mm | 3,0 mm | 126928 |

| Material |

|---|

| • Housing: Ductile iron conforming to ASTM A536, Klasse 65-45-12; EN 1563; ISO 1083 |

| • Track bolts: made of carbon steel with oval neck (metric) zinc electroplated |

| • Heavy hex nuts: made of carbon steel per ASTM A563M Klasse 9 (metric) |

| • Pipe preparation: Victaulic StrengThin™ 100 groove profile |

| Housing coating |

|---|

| • Standard: Hot dipped galvanized |

| • Optional: Orange enamel |

| • Optional: Blue zinc coating; Atmospheric corrosivity category C4 in accordance with ISO 12944 |

Rigid coupling, installation-ready for thin wall stainless steel pipe

Victaulic® StrengThin™ 100 System - Style E497

GASKET-SPECIFICATION

| Grade „EHP” EPDM |

|---|

| • EHP (Red and Green stripe color code)) |

| • Temperature range -34 ºC to +120 ºC/-30 ºF to +250 ºF. |

| • May be specified for hot water service within the specified temperature range plus |

| a variety of dilute acids, oil-free air and many chemical services. |

| • UL Classified in accordance with ANSI/NSF 61 for cold +73ºF/+23ºC and |

| hot +180ºF/+82ºC potable water service and ANSI/NSF 372. |

| • NOT COMPATIBLE FOR PETROLEUM SERVICES OR STEAM SERVICES. |

| Grade „EF” EPDM |

|---|

| • EPDM (Green “X” color code) |

| • Temperature range -34 °C to +110 °C/-30 °F to +230 °F. |

| • May be specified for hot and cold water service within the specified temperature range plus |

| a variety of dilute acids, oil-free air and many chemical services. |

| • WRAS approved material to BS 6920 for cold and hot potable water service |

| up to +65 °C/+149 °F. |

| • DVGW approved material per DVGW W 270, KTW 1.3.13, |

| and EN 681-1 Type WA cold potable and Type WB hot potable water service |

| • NOT COMPATIBLE FOR USE WITH PETROLEUM SERVICES OR STEAM SERVICES. |

| • Grade „T” Nitrile |

|---|

| • Nitrile (Orange stripe color code) |

| • Temperature range -29 °C to +82 °C/-20 °F to +180 °F. |

| • May be specified for petroleum products, hydrocarbons, air with oil vapors, and vegetable |

| and mineral oils within the specified temperature range. |

| • Not compliant for hot dry air over +60 °C/+140 °F and water over +66 °C/+150 °F. |

| • COMPATIBLE FOR USE WITH HOT WATER SERVICES OR STEAM SERVICES. |

Exclusively for use with fittings, valves, accessories and pipe which feature ends

formed with the Victaulic StrengThin™ 100 groove profile.

This view is not optimized for mobile devices.

You can change back to desktop view.

This view is not optimized for mobile devices.

You can change back to desktop view.