- Butt welding fittings

- bends

- T- X- Y- pieces

- T- and Y-bends

- reducers

- caps and heads

- collars

- branch saddles

- orbital fittings

- ANSI / ASME

- Industrial valves

- ball valves

- actuators

- drain cocks

- gate valves

- globe valves

- non-return valves

- Y-strainers

- control technology

- Flanges

- welding neck flanges

- threaded flanges

- blind flanges

- plate flanges

- loose plate flanges

- collars

- flange-fittings

- ANSI/ ASME

- other

- Systems

- TEEKAY

- Victaulic

- press fittings

- quick couplings

- clamp connections

- cutting rings

- DIN 11864/ DIN 11853

- railing construction

- Beverage fittings

- unions

- fittings

- pipe clamps

- Tri-Clamp

- valves & cocks

- flange connections

- inspection glasses

- filter & strainers

- spray balls

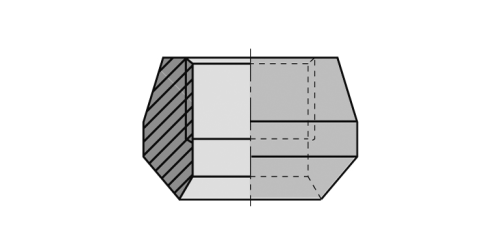

outlet, reducing - 3000 lbsOL3000

outlet, reducing - 3000 lbs ASTM A182 MSS SP-97

General

These fittings are not standardised and are manufactured in accordance

with the recommendations of the ASME B 31.3. code

Material

ASTM A 105 - A 350 - A 182 - A694; manufactured by forging

Range

Class 3000 : 1/8” to 4” / Class 6000 :1/2” to 2”

Description

This type of fittings is installed either straight or at an angle to the main pipe.

As the bearing surface fits the shape of the pipe exactly, the outside diameter

of the pipe must be known. Range : NPS 3/8" to 60". The main pipe and the

fittings are connected by means of a fillet weld.

The fitting and the branch pipe can be connected in several different ways.

Outlet radius of branch fittings have been unified in order to allow, generally

speaking up to size 4", the use of same fitting on different run pipe sizes, with

a maximum gap of 1/32" (0,8 mm) between the top of the run pipe and the base

of the fitting. For outlet sizes over 4", usually a specific radius is required for each

run size. Each fitting is marked with its nominal size (outlet diameter) and the

range of run sizes on which it can be welded.

extended product description

Stainless steel fittings PN 10 (ECO-Line) outlet

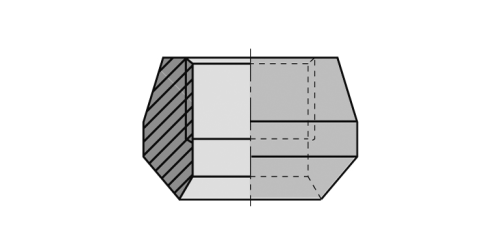

outlet, reducing - 3000 lbsOL3000

General

These fittings are not standardised and are manufactured in accordance

with the recommendations of the ASME B 31.3. code

Material

ASTM A 105 - A 350 - A 182 - A694; manufactured by forging

Range

Class 3000 : 1/8” to 4” / Class 6000 :1/2” to 2”

Description

This type of fittings is installed either straight or at an angle to the main pipe.

As the bearing surface fits the shape of the pipe exactly, the outside diameter

of the pipe must be known. Range : NPS 3/8" to 60". The main pipe and the

fittings are connected by means of a fillet weld.

The fitting and the branch pipe can be connected in several different ways.

Outlet radius of branch fittings have been unified in order to allow, generally

speaking up to size 4", the use of same fitting on different run pipe sizes, with

a maximum gap of 1/32" (0,8 mm) between the top of the run pipe and the base

of the fitting. For outlet sizes over 4", usually a specific radius is required for each

run size. Each fitting is marked with its nominal size (outlet diameter) and the

range of run sizes on which it can be welded.

This view is not optimized for mobile devices.

You can change back to desktop view.

This view is not optimized for mobile devices.

You can change back to desktop view.