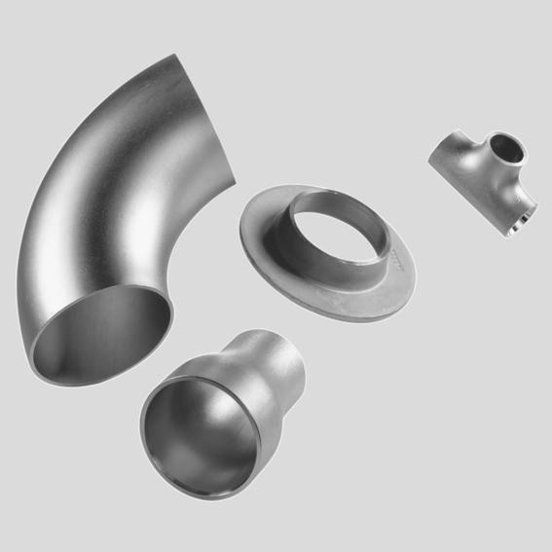

Stainless steel weld fittings

Fittings for welding in stainless austenitic and austenitic-ferritic steels in accordance with DIN EN 10253. Part 3 without special test requirements and Part 4 with special test requirements.

We store fittings such as pipe bends, T-pieces and reducers in welded and seamless designs as well as fittings with orbital weld ends.

Materials: 1.4307, 1.4541, 1.4404, 1.4571, 1.4539, 1.4462, 1.4828

All fittings are accompanied by an acceptance test certificate 3.1

Threaded stainless steel fittings

We offer threaded fittings in 3 product lines

The fittings of the ECO-Line are not subject to any construction dimension standards. The parts are not interchangeable, since we obtain this fitting design from different plants. Pressure rating PN 10.

For the fittings standardized according to ISO 4144, we guarantee consistent dimensions. The parts are interchangeable. These fittings are accompanied by with acceptance test certificate 3.1. CAD drawings in 3D step format are available for these fittings on our product pages. Pressure rating PN 16/ 20.

The fittings of the Pro-Line are made of solid material or forged. These fittings have a PED pressure approval. Pressure rating PN 100/ 64/ 40. Materials available: 1.4307, 1.4541, 1.4571, 1.4404, 1.4539, 1.4462, 1.4828.

Threaded version: acc. to ISO 7-1 for thread-sealing connections and acc. to DIN ISO 228-G for non-thread-sealing connections.

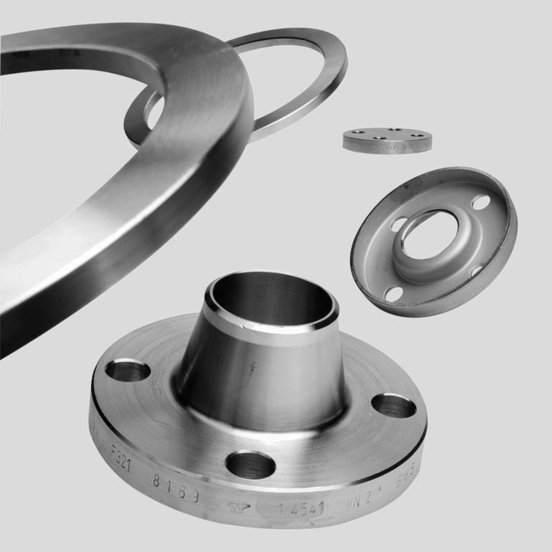

Stainless steel flanges

Round flanges for pipes, valves, fittings and accessories according to DIN EN 1092-1. This European standard specifies the flange types and their sealing surfaces, dimensions. Tolerances, thread, screw size, surface quality of the sealing surfaces of the flange connection, marking, material, pressure/temperature assignment.

We supply the flanges in the nominal sizes DN 10 to DN 1000 and in the pressure stages PN 6 to PN 400.

We also store flat flanges with reduced blade thickness in accordance with DIN EN 1092-1.

Materials: 1.4307, 1.4571, 1.4404, 1.4462, 1.4539

We also store loose flanges in aluminium and pressed sheet metal.

Industrial valves made of stainless steel

Our range of valves includes gate valves, valves, strainers, non-return valves and ball valves. Our fittings are available with threaded, welded and flanged ends.

Material: 1.4408

We also build ball valves for you as automated units. Optionally with pneumatic actuator single-/ double-acting or with electric actuator.

Fittings for the food and chemical industry

made of stainless steel

DIN 11851 - Tube fittings for rolling in and butt welding

DIN 11852 - T-pieces, bends and reducers for welding on

These standards apply to dimensions, design and materials of fittings for nominal sizes DN 10 to DN 200.

for butt welding for dimensions of longitudinally welded pipes according to EN 10357.

Material: AISI 304L and AISI 316L

Seals: EPDM, VMQ, FKM, PTFE

Clamp connections acc. to DIN 32676

for stainless steel pipes

These compounds are used in the food, beverage, chemical, pharmaceutical and cosmetics industries as well as in biotechnology, filter and water treatment technology.

We store clamp connections in the DIN, ISO and ASME dimension series.

Material: AISI 304/ 304L and AISI 316L

Seals: EPDM, VMQ, FKM, PTFE

Teekay pipe coupling system

With Teekay pipe couplings, smooth pipes can be connected quickly and easily without having to flange, weld, groove or thread them. You can cut the pipes to length on site, join them together and connect them with a pipe coupling. This saves space, weight, time and therefore costs for every installation.

Each coupling consists of a housing, a seal and a closure. The purpose of the housing is to enclose the seal when the cap is tightened and to press it against the pipe surface. The seal pulls the two ends of the housing together so that it evenly surrounds the entire circumference of the tube.

The system includes tension-resistant (Axilock) and non-tension-resistant (Axiflex), repair and stepped couplings.

Victaulic - grooved technology

Grooved couplings with grooved shapes, grooved fittings and grooved accessories (such as filters and suction diffusers) are used in countless piping applications around the world.

The pipe groove is created by forming or machining a groove into the ends of two pipes. A gasket wraps around and around the pipe ends, the coupling halves wrap around the gasket and sit in the pipe grooves, and the nuts are tightened with a wrench to hold everything together.

Original Groove System (OGS)

STRENGTHIN™ 100 SYSTEM

Installation supplies

Flat steel pipe clamps according to DIN 3567-Form A, also Form B and D. Made of stainless steel in all common sizes from stock.

Screw pipe clamps with sound insulation rubber insert and welded nut made of V4A stainless steel.

Round steel/U-bolts according to DIN 3570 Form A and B; long RB bows similar to DIN 3570; long and short PP and PA pipe supports; square bows, rectangular bows; round steel bows with bracket.

about us

about us