- Butt welding fittings

- bends

- T- X- Y- pieces

- T- and Y-bends

- reducers

- caps and heads

- collars

- branch saddles

- orbital fittings

- ANSI / ASME

- Industrial valves

- ball valves

- actuators

- drain cocks

- gate valves

- globe valves

- non-return valves

- Y-strainers

- control technology

- Flanges

- welding neck flanges

- threaded flanges

- blind flanges

- plate flanges

- loose plate flanges

- collars

- flange-fittings

- ANSI/ ASME

- other

- Systems

- TEEKAY

- Victaulic

- press fittings

- quick couplings

- clamp connections

- cutting rings

- DIN 11864/ DIN 11853

- railing construction

- Beverage fittings

- unions

- fittings

- pipe clamps

- Tri-Clamp

- valves & cocks

- flange connections

- inspection glasses

- filter & strainers

- spray balls

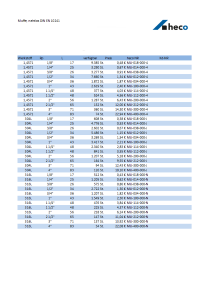

O-ring DIN 11864/DIN 11853AOR

O-ring DIN 11864/DIN 11853 f. Aseptic-/hygiene-connection

Fields of application

Popular areas of application are the biotechnology, cosmetics, chemical, pharmaceutical, and

food and beverage industries.

Materials

EPDM, VMQ, FKM, EPDM + FKM USP Class VI, PTFE-FKM seamlessly sheathed; FDA compliant ;

Installation

The O-ring is inserted in the groove flange during installation, which automatically holds the O-ring in place. The collar flange is then placed against it so that both flanges engage each other.The flanges and the O-ring are therefore coaxially centered. After that, the screws are inserted through the holes drilled in the flanges so that the heads of the screws are on the outer surface of one flange and the threads of the screws stick out of the other flange. The nuts are screwed onto these threads andevenly tightened until the faces of the flanges come into contact with each other. The O-ring is deformed by this so that a smooth passage free of dead space and a

sealed connection are produced.

extended product description

DIN 11864/ DIN 11853 flange connections Aseptic DIN 11864-2 O-rings

O-ring DIN 11864/DIN 11853AOR

Fields of application

Popular areas of application are the biotechnology, cosmetics, chemical, pharmaceutical, and

food and beverage industries.

Materials

EPDM, VMQ, FKM, EPDM + FKM USP Class VI, PTFE-FKM seamlessly sheathed; FDA compliant ;

Installation

The O-ring is inserted in the groove flange during installation, which automatically holds the O-ring in place. The collar flange is then placed against it so that both flanges engage each other.The flanges and the O-ring are therefore coaxially centered. After that, the screws are inserted through the holes drilled in the flanges so that the heads of the screws are on the outer surface of one flange and the threads of the screws stick out of the other flange. The nuts are screwed onto these threads andevenly tightened until the faces of the flanges come into contact with each other. The O-ring is deformed by this so that a smooth passage free of dead space and a

sealed connection are produced.

This view is not optimized for mobile devices.

You can change back to desktop view.

This view is not optimized for mobile devices.

You can change back to desktop view.