- Butt welding fittings

- bends

- T- X- Y- pieces

- T- and Y-bends

- reducers

- caps and heads

- collars

- branch saddles

- orbital fittings

- ANSI / ASME

- Industrial valves

- ball valves

- actuators

- drain cocks

- gate valves

- globe valves

- non-return valves

- Y-strainers

- control technology

- Flanges

- welding neck flanges

- threaded flanges

- blind flanges

- plate flanges

- loose plate flanges

- collars

- flange-fittings

- ANSI/ ASME

- other

- Systems

- TEEKAY

- Victaulic

- press fittings

- quick couplings

- clamp connections

- cutting rings

- DIN 11864/ DIN 11853

- railing construction

- Beverage fittings

- unions

- fittings

- pipe clamps

- Tri-Clamp

- valves & cocks

- flange connections

- inspection glasses

- filter & strainers

- spray balls

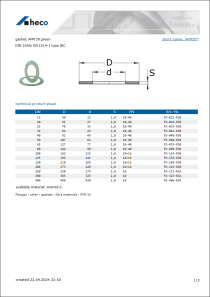

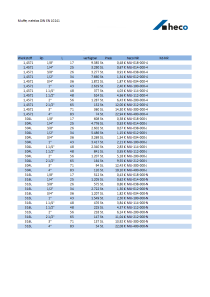

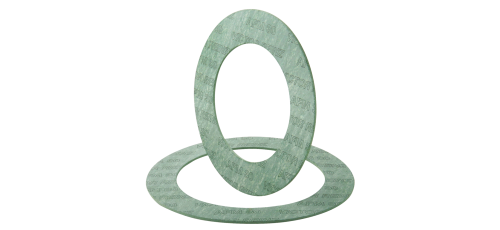

gasket, AFM 30 greenAFM30

gasket, AFM 30 green DIN 2690/ EN 1514-1 type IBC

VICTOR REINZ - AFM 30

As of: 03/2006

> Materials

AFM 30 is a seal material free of asbestos. It contains aramid fibers and otherasbestos

substitutes with high temperature resistance that are combined with high-quality elastomers at

high pressure and high temperature.

> Properties

AFM 30 is adaptable and possesses a very good mechanical/thermal strength, which is proven

by the high pressure stability.

It is excellently suited for sealing gases and liquids.

ASM 30 has good resistance to oil, gasoline, acids and bases.

> Applications

- in compressors, pipes, equipment, ...

- for sealing gearbox, hydraulic, low-temperature, and motor oils as well as fuels

- against Mixture made of water with frost and corrosion protection agent

- against refrigerants/freons, bases and solvent

| Approvals |

|---|

| DIN-DVGW according to DIN 3535, Part 6 FA |

| VP 401 all levels; higher thermally resistant seals |

| BAM (Bundesanstalt für Materialprüfung), in oxygen-steel pipelines up to 100 bar and 80°C |

| HTB (higher thermal resistance) acc. to DIN 3374/3376 for 0.1 bar and 1 bar and 650°C/30 min. |

| Pressure and temperature* |

|---|

| 400°C - Peak temperature temporarily |

| 250°C - Constant temperature maximal |

| 125 bar - Operating pressure maximal |

*= Maximum continuous temperature and maximum pressure must not occur at the same time

Technical data

| Requirement | Values* |

|---|---|

| Density | 1,75 - 1,95 g/cm³ |

| Annealing loss according to DIN 52 911 | < 36 % |

| Tensile strength according to ASTM F 152, quer | > 12 N/mm² |

| Tensile strength according to DIN 52 913, quer | > 9 N/mm² |

| Pressure stability according to DIN 52 913, 16 h, 300 °C | approx. 25 N/mm² |

| Pressure stability according to DIN 52 913, 16 h, 175 °C | approx. 36 N/mm² |

| Compression according to ASTM F 36/J | 7 - 15 % |

| Spring recovery according to ASTM F 36/J | > 50 % |

*= Nominal thickness 2,0 mm

Seal shapes

| Shape | Designation |

|---|---|

| IBC | level sealing face |

| SR | M/F face |

| TG | groove - spring |

| FF | with drill holes |

extended product description

other gaskets fibre materials AFM 30

gasket, AFM 30 greenAFM30

VICTOR REINZ - AFM 30

As of: 03/2006

> Materials

AFM 30 is a seal material free of asbestos. It contains aramid fibers and otherasbestos

substitutes with high temperature resistance that are combined with high-quality elastomers at

high pressure and high temperature.

> Properties

AFM 30 is adaptable and possesses a very good mechanical/thermal strength, which is proven

by the high pressure stability.

It is excellently suited for sealing gases and liquids.

ASM 30 has good resistance to oil, gasoline, acids and bases.

> Applications

- in compressors, pipes, equipment, ...

- for sealing gearbox, hydraulic, low-temperature, and motor oils as well as fuels

- against Mixture made of water with frost and corrosion protection agent

- against refrigerants/freons, bases and solvent

| Approvals |

|---|

| DIN-DVGW according to DIN 3535, Part 6 FA |

| VP 401 all levels; higher thermally resistant seals |

| BAM (Bundesanstalt für Materialprüfung), in oxygen-steel pipelines up to 100 bar and 80°C |

| HTB (higher thermal resistance) acc. to DIN 3374/3376 for 0.1 bar and 1 bar and 650°C/30 min. |

| Pressure and temperature* |

|---|

| 400°C - Peak temperature temporarily |

| 250°C - Constant temperature maximal |

| 125 bar - Operating pressure maximal |

*= Maximum continuous temperature and maximum pressure must not occur at the same time

Technical data

| Requirement | Values* |

|---|---|

| Density | 1,75 - 1,95 g/cm³ |

| Annealing loss according to DIN 52 911 | < 36 % |

| Tensile strength according to ASTM F 152, quer | > 12 N/mm² |

| Tensile strength according to DIN 52 913, quer | > 9 N/mm² |

| Pressure stability according to DIN 52 913, 16 h, 300 °C | approx. 25 N/mm² |

| Pressure stability according to DIN 52 913, 16 h, 175 °C | approx. 36 N/mm² |

| Compression according to ASTM F 36/J | 7 - 15 % |

| Spring recovery according to ASTM F 36/J | > 50 % |

*= Nominal thickness 2,0 mm

Seal shapes

| Shape | Designation |

|---|---|

| IBC | level sealing face |

| SR | M/F face |

| TG | groove - spring |

| FF | with drill holes |

This view is not optimized for mobile devices.

You can change back to desktop view.

This view is not optimized for mobile devices.

You can change back to desktop view.