- Butt welding fittings

- bends

- T- X- Y- pieces

- T- and Y-bends

- reducers

- caps and heads

- collars

- branch saddles

- orbital fittings

- ANSI / ASME

- Industrial valves

- ball valves

- actuators

- drain cocks

- gate valves

- globe valves

- non-return valves

- Y-strainers

- control technology

- Flanges

- welding neck flanges

- threaded flanges

- blind flanges

- plate flanges

- loose plate flanges

- collars

- flange-fittings

- ANSI/ ASME

- other

- Systems

- TEEKAY

- Victaulic

- press fittings

- quick couplings

- clamp connections

- cutting rings

- DIN 11864/ DIN 11853

- railing construction

- Beverage fittings

- unions

- fittings

- pipe clamps

- Tri-Clamp

- valves & cocks

- flange connections

- inspection glasses

- filter & strainers

- spray balls

Teekay Axilock-S pipe couplingTAFP.

Teekay Axilock-S pipe coupling - axially restrained - integrated fire protection ohne VDS Zulassung

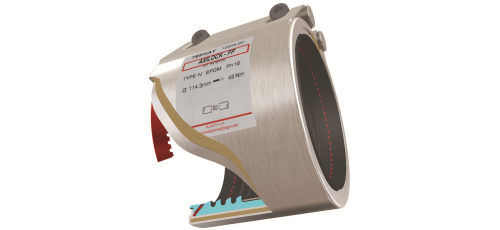

Axilock-FP

The Axilock- FP represents the ultimate in high security fire protected mechanical pipe couplings.

With its unique internal fire sleeve and double casing design it is plain to see why this coupling is

the primary pipe connection of choice in the marine and naval market sectors. The Axilock- FP

has been tested to military standards for shock and fire resistance and is fully compliant with

current IACS regulations.

Sizes

21,3 to 219,9 mm

The above tables are guides to the most common sizes. Couplings to suit specific outside

diameters not listed may be manufactured to order.

Approvals

- Type Approved by all the major marine classification bodies.

- Compliant with current IACS regulations, including pressure pulsation, vibration and

minimum burst requirements.

- Fire tested to ISO 19921/19222

- VdS - certificated

Sizes with VdS certificated :

| Sizes | Pipe* | Torque (Nm)** | bar |

|---|---|---|---|

| 42,4 | 42,4 x 2,3 | 30 | 16 |

| 48,3 | 48,3 x 2,3 | 30 | 16 |

| 60,3 | 60,3 x 2,3 | 30 | 16 |

| 76,1 | 76,1 x 2,6 | 30 | 16 |

| 88,9 | 88,9 x 2,9 | 45 | 16 |

| 108,0 | 108,0 x 2,9 | 60 | 12,5 |

| 114,3 | 114,3 x 3,2 | 60 | 12,5 |

| 133,0 | 133,0 x 3,6 | 83 | 10 |

| 139,7 | 139,7 x 3,6 | 83 | 10 |

| 159,0 | 159,0 x 4,0 | 120 | 10 |

| 168,3 | 168,3 x 4,0 | 120 | 10 |

(*) = Pipe O.D. x Min. wall thickness - (**) = Tightening torque

Material Selection

| Type | Casing | Fasteners |

|---|---|---|

| Type I | AISI 304/ 1.4301 | Alloy steel, PTFE coated |

| Type II | AISI 304/ 1.4301 | AISI 316/ 316L |

| Type IV | AISI 316L/ 1.4404 | AISI 316/ 316L |

Temperature

| Gasket | Temperature |

|---|---|

| EPDM | -20°C to +100°C |

| NBR | -20°C to +80°C |

| HNBR | -20°C to +150°C |

| FKM | -20°C to +180°C |

Working pressure

Figures are based on typical values for standart wall carbon steel pipe.

Minimum burst is 4 times working pressure for marine applications.

For industrial and land- based applications. Minimum burst is 1.5 times working pressure.

ohne VDS Zulassung

extended product description

Stainless steel TEEKAY special versions FP Ultra > 219,1 mm

Teekay Axilock-S pipe couplingTAFP.

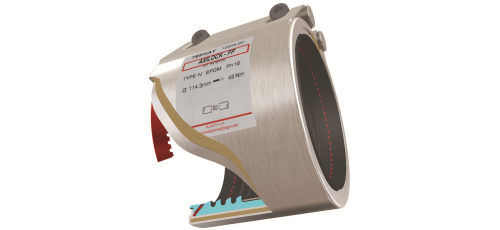

Axilock-FP

The Axilock- FP represents the ultimate in high security fire protected mechanical pipe couplings.

With its unique internal fire sleeve and double casing design it is plain to see why this coupling is

the primary pipe connection of choice in the marine and naval market sectors. The Axilock- FP

has been tested to military standards for shock and fire resistance and is fully compliant with

current IACS regulations.

Sizes

21,3 to 219,9 mm

The above tables are guides to the most common sizes. Couplings to suit specific outside

diameters not listed may be manufactured to order.

Approvals

- Type Approved by all the major marine classification bodies.

- Compliant with current IACS regulations, including pressure pulsation, vibration and

minimum burst requirements.

- Fire tested to ISO 19921/19222

- VdS - certificated

Sizes with VdS certificated :

| Sizes | Pipe* | Torque (Nm)** | bar |

|---|---|---|---|

| 42,4 | 42,4 x 2,3 | 30 | 16 |

| 48,3 | 48,3 x 2,3 | 30 | 16 |

| 60,3 | 60,3 x 2,3 | 30 | 16 |

| 76,1 | 76,1 x 2,6 | 30 | 16 |

| 88,9 | 88,9 x 2,9 | 45 | 16 |

| 108,0 | 108,0 x 2,9 | 60 | 12,5 |

| 114,3 | 114,3 x 3,2 | 60 | 12,5 |

| 133,0 | 133,0 x 3,6 | 83 | 10 |

| 139,7 | 139,7 x 3,6 | 83 | 10 |

| 159,0 | 159,0 x 4,0 | 120 | 10 |

| 168,3 | 168,3 x 4,0 | 120 | 10 |

(*) = Pipe O.D. x Min. wall thickness - (**) = Tightening torque

Material Selection

| Type | Casing | Fasteners |

|---|---|---|

| Type I | AISI 304/ 1.4301 | Alloy steel, PTFE coated |

| Type II | AISI 304/ 1.4301 | AISI 316/ 316L |

| Type IV | AISI 316L/ 1.4404 | AISI 316/ 316L |

Temperature

| Gasket | Temperature |

|---|---|

| EPDM | -20°C to +100°C |

| NBR | -20°C to +80°C |

| HNBR | -20°C to +150°C |

| FKM | -20°C to +180°C |

Working pressure

Figures are based on typical values for standart wall carbon steel pipe.

Minimum burst is 4 times working pressure for marine applications.

For industrial and land- based applications. Minimum burst is 1.5 times working pressure.

This view is not optimized for mobile devices.

You can change back to desktop view.

This view is not optimized for mobile devices.

You can change back to desktop view.